Analyzing the Potential of LED Strip Light in Machine Vision Systems: Illuminating Objects for Inspection Cameras in Factories

Machine vision systems play a crucial role in various industries, particularly in factories where automated inspections are essential for quality control. One vital component of these systems is illumination, as it enables inspection cameras to capture accurate and reliable images of objects under scrutiny. LED strip lights have gained significant attention as a potential lighting solution for machine vision systems due to their versatility and efficiency. In this article, we will objectively analyze the possibilities and benefits of using LED strip lights in illuminating objects for inspection cameras in factories.

Advantages of LED Strip Light:

LED strip lights offer several advantages that make them suitable for machine vision systems:

Flexibility and Adaptability: LED strip lights can be easily cut and reconfigured to fit specific lighting requirements. This flexibility allows for precise and customized illumination, enabling optimal lighting conditions for inspection cameras in different environments.

Energy Efficiency: LED technology is renowned for its energy efficiency. LED strip lights consume significantly less power compared to traditional lighting sources, resulting in reduced energy costs for factories while maintaining a high level of brightness.

Longevity and Reliability: LED strip lights have a longer lifespan compared to traditional lights. Their robust design and solid-state construction make them resistant to shock, vibration, and temperature variations, ensuring consistent and reliable performance in industrial settings.

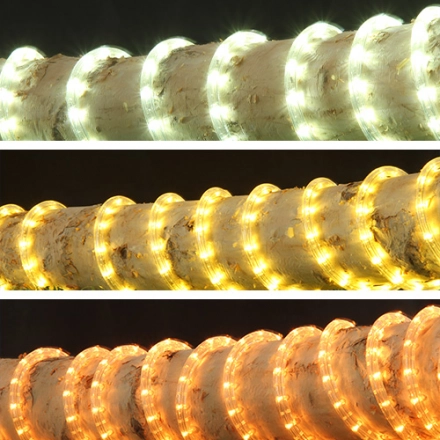

Controllability: LED strip lights can be easily controlled and adjusted to achieve the desired intensity, color temperature, and even dynamic lighting effects. This capability is crucial for machine vision systems, as it allows for precise control of lighting parameters to enhance image quality and inspection accuracy.

Challenges and Considerations:

While LED strip lights offer significant advantages, there are certain challenges and considerations to keep in mind:

Uniformity: Achieving uniform illumination across a large area can be challenging with LED strip lights due to their linear design. Additional measures, such as diffusers or reflectors, may be necessary to ensure even lighting distribution for consistent image capture.

Heat Dissipation: LED strip lights can generate heat, especially at higher brightness levels. Proper heat dissipation mechanisms, such as heat sinks or active cooling systems, must be implemented to prevent overheating and maintain the longevity of the lights.

Spectral Output: The spectral output of LED strip lights should be carefully considered to ensure compatibility with the specific requirements of machine vision systems. The spectral distribution should match the sensitivity of the inspection cameras to avoid color inaccuracies or distortions in captured images.

Conclusion:

LED strip lights hold significant potential for illuminating objects in machine vision systems for inspection cameras in factories. Their flexibility, energy efficiency, longevity, and controllability make them an attractive choice for enhancing image quality and inspection accuracy. However, challenges such as uniformity, heat dissipation, and spectral output need to be addressed to ensure optimal performance. With further advancements and innovations in LED technology, the potential of LED strip lights in machine vision systems is likely to expand, contributing to more efficient and reliable automated inspections in factories.